Designed to meet your specific needs.

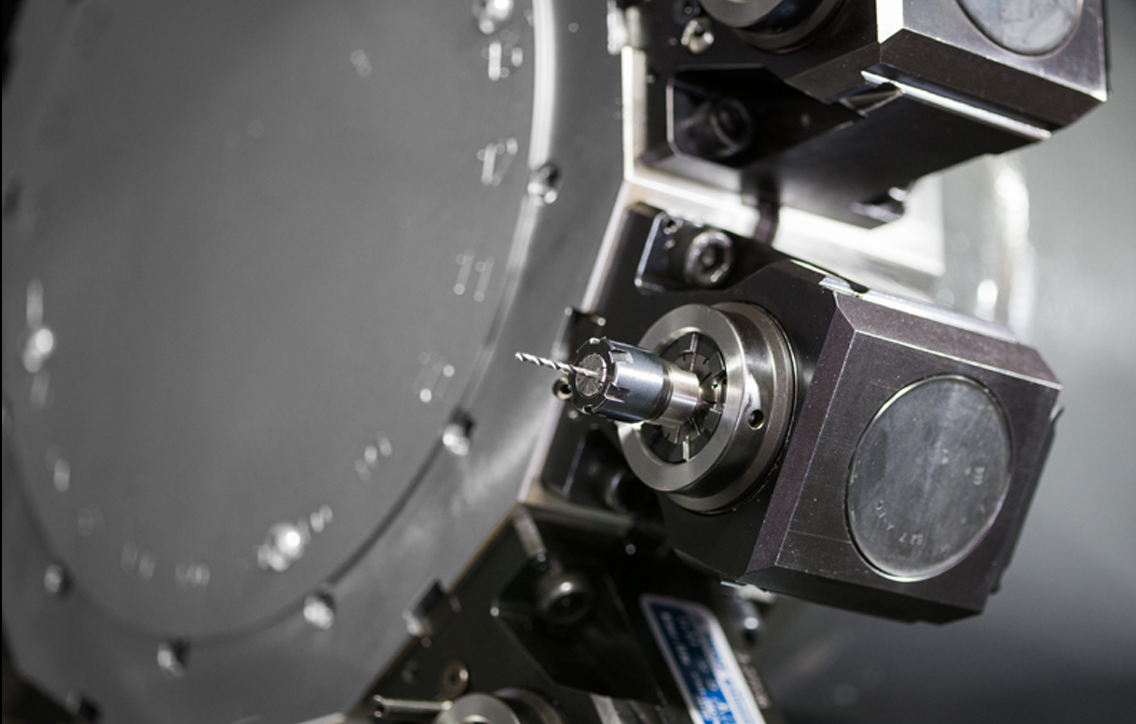

Bespoke mouldings

At the design process we will work with you to determine the optimum number of cavities to meet your volume requirements and also your budget. We can cater for any size production run, from 50 pieces to 50,000.

Whatever your volume requirement our mould room is equipped with an extensive range of fully automated presses up to 400 tonnage. Our range of Panstone Precision compression moulding machines ensure excellence in quality.

Capabilities

- Suite of Panstone Precision compression moulding machines with standard platen sizes 500mm x 600mm gives flexibility to tooling design and size.

- Moulding is enhanced with the addition of vacuum chambers to improve finish with complex component design.

- Extra Large purpose built Tung Yu moulding machine provided large platen sizes up to 1.6m x 0.8m allowing us to take on large moulded components.

Compounds

The choice of rubber compound is up to you. Whether you are looking for: abrasion or tear resistance; elongation break or compression set; non conductivity, extreme operating temperatures, flame retardancy or strength, there will be a compound to suit.

Our stock compounds include:

- Hypalon

- Neoprene

- EPDM

- Nitrile

- Polyurethane

- Hydrogenated Nitrile

- VAMAC

- Viton

- Natural Rubber

- High Performance Low Smoke Low Toxicity elastomers

- Silicone – any grade

- Compounds can be colour matched to the nearest Panstone/RAL reference.

Speciality moulding

We are able to offer speciality moulding services including:

• Rubber to metal bonding

• Rubber bonding to electronic components

• Rubber bonding to extrusion

• Flocking services to rubber

Hours

8-5pm

Mon - Fri

(open until 1pm on Friday)

Service area

Worldwide

Contact our moulding specialist

01795 535008

info@j-coker.co.uk

FOOD INDUSTRY: CASE STUDY

"When an idea was pitched in one of our meetings, I had to look for a rubber manufacturer who could work with us, not against us from a simple drawing.

J Coker came highly recommended from multiple sources and from that drawing through to production, they have helped, guided and supplied us a top quality product.

With a common-sense approach but professional finish, I cannot recommend the services of this company enough and that is hard to find these days.

Thank you, well done and I look forward to our partnership growing in the future."

Lee Deeble

Health, Safety & Facilities Manager

We supply to chefs in London and the south east with a seven day a week service.

- Our Mission – to provide chefs with great service, great produce and less hassle

- Our Produce – we have over 4,500 products and a range that is always growing. We stock; dairy, frozen, dry goods chilled non-food and also some quirky specialist items too

- Our Office - manned 7 days a week, processing orders up until midnight for next day delivery. We have a friendly and knowledgeable customer service team who are here to answer your queries and take your orders via phone and email

- Our Warehouse - now based in Dartford, Kent, a stones throw from the M25 and Dartford crossing into London. We run a live stock system and have the latest barcode scanners to scan your goods when they are loaded onto the vans

- Our Fleet – our multi-temperature vehicles are frequently serviced, we have GPS tracking software on the fleet and we always aim to deliver at a time

convenient to you

RAIL: CASE STUDY

"J Coker Ltd have been a key Tier 1 supplier to LPA for a number of decades now. Their quality, service and experience have ensured our success with a number of major UK Rail projects over the past couple of years.

They remain our first choice supplier for all our rubber moulded components for our aviation and rail product ranges. I would highly recommend J Coker Ltd."

Neil Sharpe, Purchasing Manager, LPA Connection Systems.

LPA Connection Systems design and manufacture flexible product solutions for complex electrical inter-connection applications. Their products include:

- Inter-car connection systems for rail rolling stock;

- Ground power supply aviation products including connectors and cable carriers;

- Niphan range of industrial connectors for rugged environments.

LPA Connection systems is ISO 9001 certified and is approved by companies such as Bombardier Transportation, Hitachi Rail, Crossrail, London Underground, London Heathrow and Gatwick Airports.

Our methods

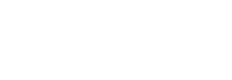

Tool moulding

The first stage in the design and development process. J Coker’s on-site tool room is headed up by Andrew Coker, a highly experienced tool maker.

Fabrication

Fabrication services covers a multitude of products, particularly those too large to be moulded. From hand-made bellows and sleeves and rubber lined pipes to cut gaskets, washers and rubber sheeting.

Casting discs

We manufacture our own range of rubber and silicone casting discs for centrifugal casting.

“A testimonial from a happy client."

Lynda Jones

“A testimonial from a happy client."

Harley Baker

“A testimonial from a happy client."